Pot stills are special vessels – they possess this ability (superpower, really) to transform this slightly acidic, alcoholic, carbonated liquid into a more refined, grown-up version of itself. To some, they’re just a shiny pot with a funny looking arm, used to produce higher-proof alcohol; while not untrue, pot stills can be quite diverse. Coming in a range of heights, widths, shapes, and materials – from round to square, squat to tall, and copper to clay – each still can have its own character. Some might even have unique damage or dents that the distiller believes is the “secret sauce.”

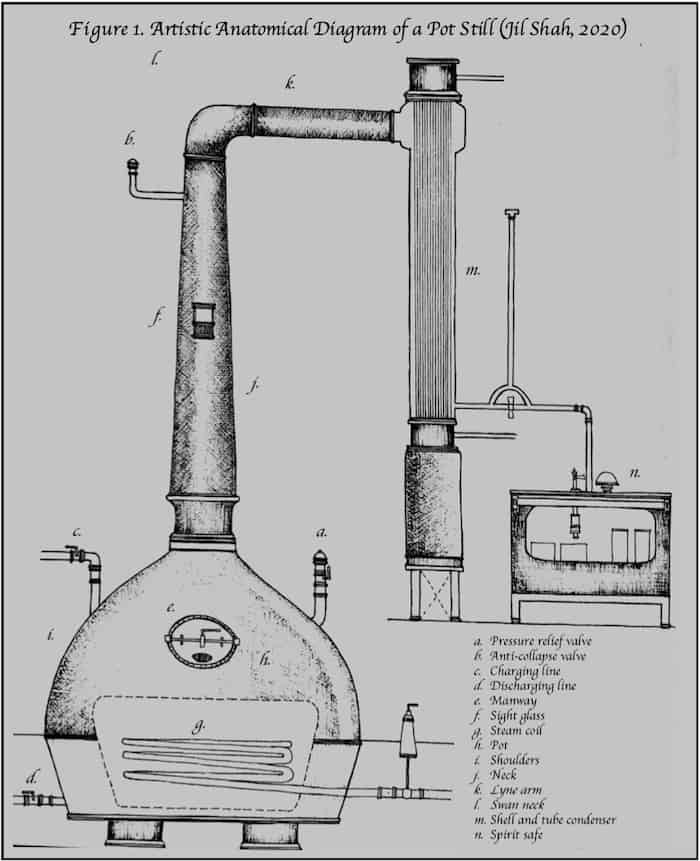

Many of these characteristics can impact the process or the flavor profile of the spirit. Either way, the still is the heart and soul of the distillery and their uniqueness should be celebrated. However, there are some components that are essential to operation, which can be categorized as: safety, practical features and heating, reflux and flavor development, and condensing and collection. Certainly, there can be variations within each category, and this is what makes distillation such an exciting venture.

Although, there is one area where minimal variation should exist – safety.

Safety

Distillation is an inherently dangerous process. Heating a solution to remove and concentrate alcohol by vaporization creates a risk for fires and explosions. Therefore, equipment must be designed and operated by trained professionals to prevent such events from occurring. Additionally, the distillery must have standard operating procedures (SOPs) to ensure correct and safe operation of the equipment.

Outside of fire suppression systems, SOPs, and facility layout, still design should incorporate a few key elements to minimize the risk of explosion or collapse. Pressure relief valves (PRVs) are spring-loaded safety valves that are designed to vent excess pressure to atmosphere when its setpoint is exceeded. However, one must also consider the flammable vapors inside the still and what might happen when they are released. Anti-collapse valves (ACVs) are installed to prevent still collapse due to the formation of a vacuum.

While the activation of the ACV possesses less risk to the operation or distillers’ safety, it does signal the occurrence of an event that could cause damage to the still. These valves are critical in minimizing the risks of explosion, damage to equipment and property, and injury of personnel. Although, safety doesn’t stop here and should be woven into every aspect of still design and operation.

Practical Features and Heating

Aside from charging and discharging lines, manways are another essential element; this is a medium-sized opening with a sealed door that allows for cleaning, inspection, and maintenance activities. While it sounds like an entrance, stills are not designed to have people inside and only trained professionals under strict supervision should enter them. When done inappropriately, entering the still can pose serious safety risks and violate safety regulations.

Sight glasses provide a window into the soul of the wash still, which gives the distiller valuable information about what is happening inside. For example, during this initial distillation, foaming can occur inside the still due to the still charge containing a lot of particulate (yeast and/or grain) and dissolved carbon dioxide; the sight glass gives the distiller visibility to prevent flare-ups.

Excessive foaming can lead to entrainment (aka “puking”) of solids or liquid in the passing vapor and into the spirit, negatively impacting quality. When observed, the distiller can mitigate entrainment by reducing the heat input.

Still heating methods have evolved as the industry has matured and two major types are in use: direct and indirect. Direct-fire is a more traditional practice, where more archaic fuels include the use of wood or coal. While direct-fire stills are still in use, most have been upgraded to more efficient gas burners or electrical elements.

Indirect-fire utilizes steam as the heating medium, typically delivered by coils and/or pans within the pot. Steam is generally preferred due to enhanced safety, improved consistency, and increased operational efficiency.

Although direct-fire has advantages, such as the creation of unique flavor profiles; this is due to the localization of heat and its intimate interaction with components within the wash or beer. In fact, some distilleries have attempted to switch to steam but quickly reverted back due to a shift in flavor profile.

While important, the heating method employed only plays a smaller role in flavor development, especially when compared with elements impacting reflux and rectification level.

Reflux and Flavor Development

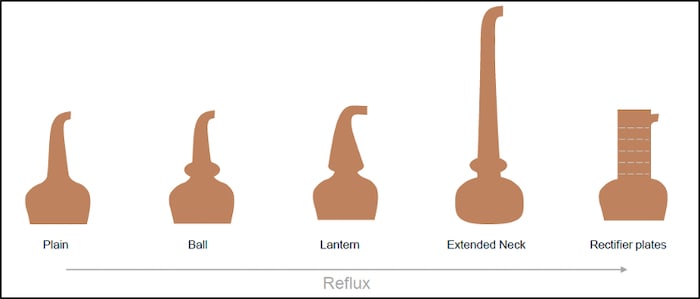

During distillation, reflux is essentially a purification step (aka rectification) where liquid is vaporized and condenses back into itself. Rectification is closely tied to the volatility of the components of the matrix. Compounds with lower volatility (water) will readily participate in reflux, therefore enriching compounds with higher volatility (ethanol) in the spirit-stream. In general, this creates a lighter flavor profile with higher alcohol content.

In batch distillation, there are several design elements that can impact the level of reflux, such as: the shoulders, neck, lyne arm, and the pot itself.

Inherently pot design is critical for practical reasons; but, standing out in importance from a rectification standpoint are the pot’s fill level and construction materials. Fill level impacts the amount of surface area that can participate in heat exchange with the environment; higher fill levels decrease the heat transfer surface area. Heat transfer is also impacted by construction materials; copper is commonplace due to its excellent heat transfer properties. This exchange helps facilitate reflux on the walls of the pot, neck, and shoulders of the still.

Thus, the shape, curvature, width, and height can all have an impact. Above the pot and shoulders is a frustoconical section called the neck. Common designs include plain, ball, lantern, and tray-inserts (in order of rectification). Pot stills with trays within their necks are referred to as hybrid stills, or batch rectifiers, as trays are key design elements of continuous distillation.

Connecting the neck to the condenser is the lyne arm. While the lyne arm’s primary function is directing vapors to the condenser, it also provides an opportunity for condensation or reflux. Depending on the angle of the lyne arm connection (aka swan neck), there can be an impact on the flavor profile with obtuse angles providing more reflux and acute angles providing the least.

Other rectification design elements exist, such as dephlegmators and purifiers. While not always essential, they provide another opportunity to create a unique spirit. Commonly, these devices use cooling water to condense the passing vapors. Dephlegmators are located in the neck of a hybrid still and the condensed liquid naturally refluxes down. Installed in a downward-sloped lyne arm, purifiers require additional piping to route the condensed liquid back to the pot.

While these partial condensers can be optional, complete condensation of the vapor is requisite in making the final spirit.

Condensing and Collection

Condensation of vapor into liquid (distillate) is usually performed by one of two condenser types: shell and tube or worm and tub. Before the advent of the modern shell and tube condenser, worm and tubs were state-of-the-art. All vapor is routed through a coiled pipe (normally copper) in a tub of cooling water and the condensed vapor is collected.

While not as efficient as their modern-day equivalent, they do have some advantages by providing potentially richer and stronger flavor profiles (i.e. meatiness). Shell and tube condensers are made of tubes within a metal cylinder (shell) filled with water; vapor enters the tubes and condenses on the water-cooled surface. Once condensed, the distiller embarks on the most critical steps of the batch distillation: cuts and collection.

Collection generally occurs through an intermediary glass box en route to collection vessel(s), called the spirit safe. This is the first opportunity the distiller has to assess and analyze the newly condensed distillate, typically by measuring alcohol with a hydrometer in the spirit safe. With this information, the distiller can determine when to divert to heads, hearts, or tails collection or to terminate distillation altogether.

Samples may also be taken for external assessments, such as appraisal of aromatic properties. Sensory and alcohol level are often used to determine cut points, although it could also be time-based. As with most elements of still design, variation exists; regardless, some version of a spirit safe is integral as the cutting process plays a vital role in final distillate quality.

Conclusion

Pot still to pot still, a “Sherry Butt-load” of variations can exist. While not entirely responsible for the amount of diversity within the whisk(e)y space or other distilled spirits categories, these differences can play a significant part. Personally, it’s exciting as a distiller and consumer to reflect on and appreciate this.

Even though some anatomical elements are essential, such as safety features, heat, and the pot itself, still design can be quite dynamic. From frustoconical configurations to dephlegmator, the distiller has many options to contemplate as the still will inevitably become the distillery’s heart and soul (dents optional).